Getting a handle on your stock is one of the most fundamental parts of running a profitable small business. It’s all about the nitty-gritty of ordering, storing, and ultimately selling your products. Think of it as the engine room of your operation – get it right, and you’ll have what customers want, when they want it, without sinking all your cash into goods that are just gathering dust.

Building Your Foundation for Smart Stock Control

If you’re running a small business in the UK, you know the feeling. Managing stock often feels like walking a tightrope. Order too much, and your cash flow grinds to a halt. Order too little, and you’re faced with empty shelves, lost sales, and unhappy customers.

Nailing this balance isn’t just an admin task; it’s a core strategy that directly impacts your bottom line and overall business health. It’s about swapping guesswork for informed, data-driven decisions. This clarity is what stops you from making those classic costly mistakes, like being stuck with a mountain of Christmas stock in February or running out of your best-seller right in the middle of a sales rush.

Why You Can’t Afford to Ignore Your Inventory

For UK businesses, the need for a solid inventory system has never been clearer. The last few years have been a masterclass in just how quickly supply chains can be disrupted. Data from the ONS showed just how wild the swings in inventory levels were between 2018 and 2021, with Brexit and the pandemic creating huge waves.

Sectors like retail and construction saw their stock levels plummet as customer habits changed overnight. It was a stark reminder that small businesses, without the deep pockets and massive warehouses of larger corporations, are often the most exposed.

This guide is here to cut through the complexity. We’ll break down inventory management into straightforward, actionable steps, helping you build a system from scratch.

At its core, great inventory management is about turning a potential business weakness into a competitive strength. It allows you to be agile, responsive to customer demand, and financially resilient, no matter what the market throws at you.

Before we dive into the “how-to,” let’s quickly summarise the core pillars we’ll be building on.

Core Pillars of Small Business Inventory Management

| Pillar | Why It Matters | Key Action |

|---|---|---|

| Valuation Method | Determines the cost of goods sold and the value of remaining stock, impacting your financial statements and tax. | Choose an appropriate method (like FIFO or FEFO) that suits your product type and business model. |

| Physical Storage | An organised space reduces picking errors, speeds up fulfilment, prevents damage, and makes stock-takes easier. | Design a logical layout for your storeroom or find flexible business storage solutions. |

| Tracking System | Provides real-time visibility of what you have, where it is, and when you need to reorder. | Select a tool that matches your scale, from a smart spreadsheet to entry-level inventory software. |

| Auditing & Routines | Regular counts and checks ensure your system’s data matches physical reality, catching discrepancies early. | Establish a routine for cycle counting or periodic full stock-takes. |

| Demand Forecasting | Helps you anticipate future sales, allowing you to order proactively and avoid stockouts or overstocking. | Analyse past sales data to identify trends and seasonality. |

By getting to grips with these five areas, you’ll be well on your way to building a reliable inventory system that not only works but actively helps your business grow.

How to Value Your Inventory: FIFO, LIFO, and FEFO

Before you can even think about tracking stock levels, you need a system for assigning a monetary value to everything on your shelves. This might sound like a job just for your accountant, but it’s a decision that hits you right in the profit margins, affects your financial statements, and can even change how much tax you owe.

Getting this right from the start gives you a true picture of your business’s financial health. The method you land on determines two massive figures: your Cost of Goods Sold (COGS) and the value of your closing inventory. Both are front and centre on your profit and loss statement. There are a few different ways of tackling this, so it’s worth understanding the options before choosing your inventory costing method.

First-In, First-Out (FIFO): The Go-To Method

The First-In, First-Out (FIFO) method is the most popular for a reason – it’s simple and it just makes sense for most businesses. It runs on the assumption that the first items you buy are the first items you sell.

Let’s imagine you run a small electronics shop in Leeds. In January, you get a delivery of headphones that cost you £50 a pair. By March, your supplier’s prices have gone up, and the next identical batch costs you £55 a pair. When someone buys headphones in April, FIFO assumes you sold one of the £50 pairs from the January batch. Easy.

This approach naturally reflects how most businesses shift their stock, making sure older items don’t get left gathering dust in the back. During periods of rising costs, FIFO also tends to result in a lower COGS, which can mean higher reported profits on paper.

Last-In, First-Out (LIFO): The (Not-for-the-UK) Alternative

Now for the opposite approach. The Last-In, First-Out (LIFO) method assumes the newest items you’ve bought are the first ones to be sold.

Back at our Leeds electronics shop, if we were using LIFO, that April sale would be matched against the most recent cost of £55.

In a climate of rising prices, this method can actually offer a bit of a tax advantage. By matching your most recent (and higher) costs against your revenue, you end up with a higher COGS, which lowers your reported profits and, in turn, your tax bill.

Heads up: LIFO isn’t permitted under the International Financial Reporting Standards (IFRS) used here in the UK. So, while you might hear about it in a global context, it’s not a legitimate option for UK businesses when preparing official financial reports.

This little detail makes FIFO the default, common-sense choice for pretty much any UK small business selling non-perishable goods.

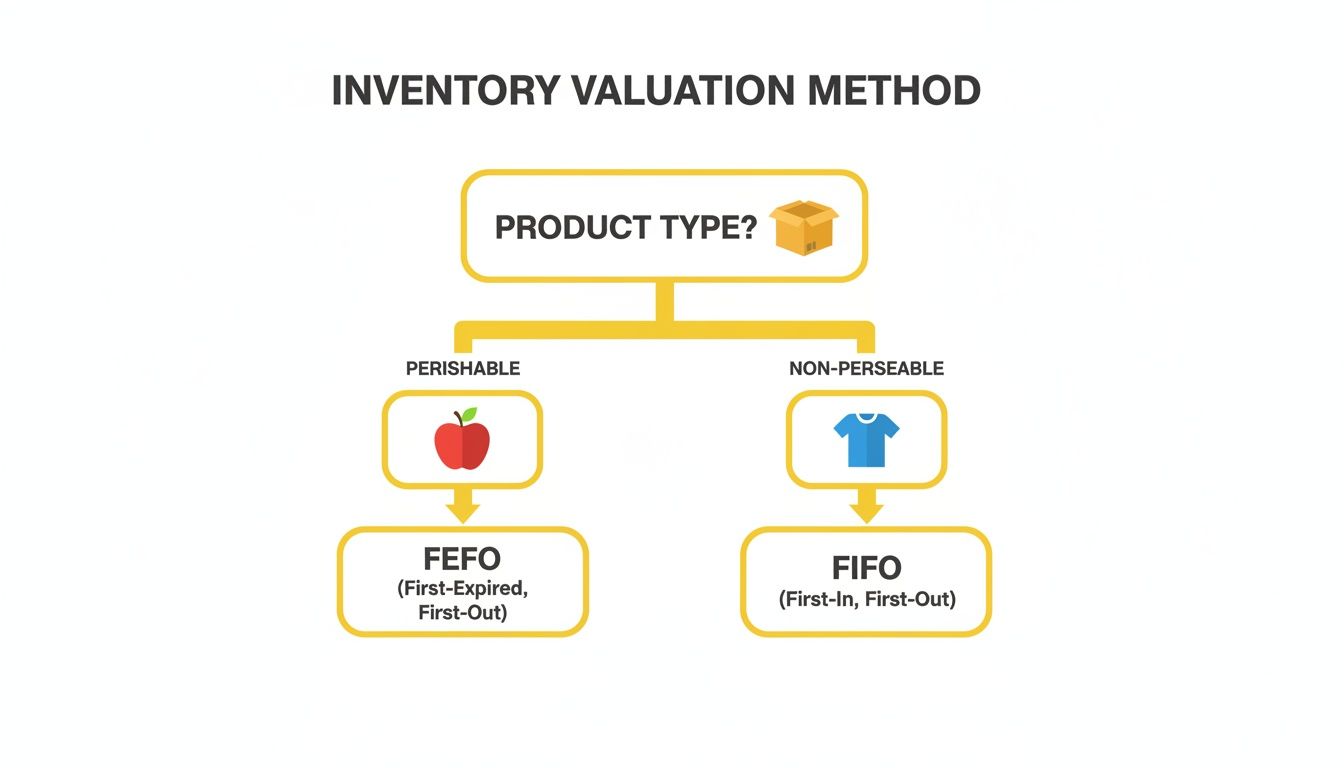

First-Expired, First-Out (FEFO): Essential for Perishables

If you sell anything with a use-by date, the First-Expired, First-Out (FEFO) method isn’t just a good idea—it’s absolutely essential. This system doesn’t care when an item arrived; it prioritises selling products based on their expiry date. The closest expiry date goes out the door first.

Think about a local bakery in Bristol. The loaves they baked yesterday must be sold before the fresh ones from this morning. It’s the only way to keep customers happy and keep waste to a minimum. FEFO is just the official name for this crucial process.

FEFO is the only way to operate for businesses like:

- Food and Drink: Cafes, grocers, and corner shops rely on it to cut down on spoilage.

- Pharmaceuticals: For chemists, it’s a matter of safety and making sure medicines are effective.

- Cosmetics: Skincare and other beauty products have a limited shelf life and need careful management.

So, what’s the takeaway? Your choice really boils down to what you sell. For most UK businesses, FIFO is the clear, compliant, and logical way forward. But if your products can expire, FEFO is your only real option.

Organising Your Physical Stock for Efficiency

A messy stockroom isn’t just an eyesore; it’s a quiet thief, stealing profits right from under your nose. Every minute your team spends hunting for a product, every picking mistake that results in a return, and every item damaged by poor storage is a direct hit to your bottom line.

Getting your physical storage sorted transforms a chaotic space—whether it’s a back room, a garage, or a self-storage unit—into a high-performance fulfilment machine. This is where the theory hits the floor. The aim is to create a system so intuitive that anyone can find anything, fast. It’s not about being tidy for the sake of it; it’s about embedding efficiency into the very bones of your operation.

Start with ABC Analysis

Before you move a single box, it’s worth doing a quick ABC analysis. This is a brilliantly simple method for categorising your stock based on its value, not just its size or cost. It works on a fundamental truth: some products matter more than others.

- ‘A’ Items: These are your superstars. They represent a small fraction of your total stock items (around 20%) but generate the lion’s share of your revenue (roughly 80%). Think best-sellers and high-margin products. These need your full attention.

- ‘B’ Items: Your solid, mid-range performers. They make up about 30% of your stock and bring in around 15% of your revenue. Important, but not critical.

- ‘C’ Items: The slow-movers and low-value bits and bobs. These items can account for 50% or more of your total stock but might only contribute 5% to your revenue.

With this knowledge, you can design your storage layout with intelligence. Your ‘A’ items should live in the most accessible, prime-real-estate locations—think waist-height shelves right next to the packing bench. This makes picking them a breeze and stock-takes less of a chore. The ‘C’ items? They can be tucked away on higher shelves or further back.

Design a Logical Layout

Once you’ve prioritised your stock, you can map out your space. A logical flow from receiving goods to sending them out is non-negotiable. I always recommend setting up clear zones for each stage of the process:

- Receiving Area: This needs to be a dedicated space right by the door. It’s where you unpack deliveries, check for damages, and verify orders without tripping over everyone else.

- Storage Area: The heart of your operation. This is where your ABC analysis comes into play. Use sturdy, vertical shelving to make the most of your headroom, and place your high-turnover items where they are easiest to grab.

- Picking and Packing Station: Set up an organised workbench with everything you need within arm’s reach: boxes, tape, void-fill, and label printers. Position it between your main stock and the dispatch point.

- Dispatch Area: A clear spot for packed orders to wait for courier collection, keeping them separate from incoming goods.

This zoned approach is your best defence against bottlenecks and wasted steps. Getting this right can be a real challenge, especially when you’re growing fast. If you’re using an external unit, our guide on how to organise your storage unit has some brilliant, practical tips that work just as well for any stockroom.

Remember, a well-organised stockroom is also a key part of your health and safety duties. Clear gangways, stable shelving, and properly stored goods are essential for preventing accidents and creating a safer place for everyone to work.

Recent economic pressures have made smart storage even more critical. In 2022, rampant inflation threw a spanner in the works for UK small businesses. Many rushed to buy stock to beat price rises, leading to overstuffed warehouses, while cash-strapped firms held back, risking stockouts. This volatility turned routine ordering into a high-stakes gamble, piling financial pressure onto the UK’s 5.5 million SMEs. You can read the full analysis of inflation’s impact on Statista.

This decision tree helps visualise which method—FEFO or FIFO—is the right fit based on your product type.

The key takeaway here is simple: if your goods are perishable, FEFO is the only way to go. For everything else, FIFO is the standard in the UK. This choice directly impacts how you physically arrange your shelves, ensuring the products that need to leave first are always at the front of the queue.

Implementing a Low-Cost Inventory Tracking System

Moving beyond a notepad and pen is a huge step towards getting your stock control right. I’ve seen countless small businesses hesitate, thinking any “system” must be expensive or complicated. But it doesn’t have to be. The journey from scribbled notes to smart automation can be a gradual, affordable process.

It all starts by swapping those unreliable paper records for a tool you already own: a spreadsheet. This simple upgrade creates a single source of truth, making your inventory management for small businesses more dependable from day one.

From Smart Spreadsheets to Basic Barcodes

The first, and frankly the most cost-effective, upgrade is a well-organised spreadsheet. This isn’t just about making a list. It’s about building a simple but powerful tool with formulas to track stock levels, calculate the value of your inventory, and even flag when you need to reorder.

To get started, create columns for the absolute essentials:

- SKU (Stock Keeping Unit): A unique code for every single product variant.

- Product Name/Description: A clear, unambiguous description.

- Supplier: Who you buy it from.

- Cost Price: What you pay for one unit.

- Stock on Hand: The current quantity you physically have.

- Reorder Level: The minimum stock level that triggers a new purchase order.

This digital ledger immediately makes your stock data searchable and far easier to update than a dusty notebook. As you sell items or get a new delivery, you just update the ‘Stock on Hand’ column. Over time, this builds a brilliant history of your sales data. To learn more about organising your goods, check out our insights on stock and inventory storage for businesses.

Eventually, as your order volume grows, that spreadsheet will start to feel clunky. This is the perfect time to introduce barcode scanning. It dramatically cuts down on human error and speeds up every single process, from checking in deliveries to picking orders. Getting started is cheaper than you’d think, too. A simple USB barcode scanner can cost as little as £20-£30. These devices are typically plug-and-play; they act just like a keyboard, zapping the barcode number straight into your spreadsheet or software.

Graduating to Entry-Level Inventory Software

While a barcode scanner and a spreadsheet is a massive improvement, it’s still a very manual system. When you find yourself spending more time updating stock levels than actually running your business, it’s time to look at entry-level inventory management software. These platforms are built for small businesses, giving you powerful features without the enterprise-level price tag.

These systems are the real game-changer. They connect your sales channels—like your Shopify store or retail till—directly to your inventory records. An item sells online, and the stock level is updated automatically everywhere. This is how you stop selling products you don’t actually have.

Many of these tools offer free or low-cost plans, often starting from around £25-£50 per month. They’re designed to scale with you, so you can add more users, products, or sales channels as your business takes off.

The real value of inventory software is automation. It handles the repetitive, error-prone tasks, freeing you up to focus on strategic decisions like product sourcing and marketing, instead of constantly counting stock.

When you’re comparing your options, the most important thing to look for is integration. Does it talk to the tools you already use, like your e-commerce platform (Shopify, WooCommerce) and your accounting software (Xero, QuickBooks)? A well-integrated system means data flows automatically, saving you from the nightmare of entering the same information in three different places. For a deeper look at what a more advanced system can do, this Odoo Inventory Management Guide is a great resource.

Comparison of Entry-Level Inventory Tracking Methods

Choosing the right system comes down to your business’s current size, complexity, and budget. What works for a simple craft stall is very different from what an online retailer with hundreds of SKUs needs. To help you decide, here’s a quick comparison of your options.

| Method | Best For | Initial Cost (£) | Pros | Cons |

|---|---|---|---|---|

| Spreadsheets | Start-ups and micro-businesses with a small, manageable number of SKUs. | £0 (using existing software) | Completely free, highly customisable, easy to get started with. | Prone to human error, not real-time, becomes unwieldy as you grow. |

| Barcode Scanning | Businesses with rising order volumes that need faster, more accurate stock counts. | £20 – £100+ | Drastically reduces data entry errors, speeds up receiving and dispatch. | Requires consistent product labelling, still relies on a manual backend. |

| Inventory Software | Growing businesses, especially in e-commerce or multi-channel retail. | £25 – £75+ per month | Real-time tracking, automates reordering, integrates with sales channels. | Monthly subscription cost, requires initial setup and some training. |

Ultimately, the goal is to pick a system that solves your current headaches without creating new ones. My advice is always to start simple, prove the process works for you, and only invest in more advanced tools when the time saved and errors avoided clearly justify the cost.

Mastering Your Routines: Counting and Forecasting

A brilliant tracking system is only as good as the numbers you feed it. Even with the best software on the planet, little discrepancies will creep in. A miscounted delivery here, a picking error there, a damaged item that wasn’t written off… it all adds up. This is precisely why disciplined routines for counting and forecasting are non-negotiable for smart inventory management for small businesses.

Think of these practices as the difference between a rough guess and a dependable business asset. When you regularly check that your physical stock matches your records, you build a foundation of accuracy. That accuracy makes every other part of your business, from ordering new stock to fulfilling customer orders, run like a well-oiled machine.

Establish Your Counting Rhythm

For most people, the word “stocktake” conjures up images of shutting down for a whole day while everyone frantically counts every last widget. That’s a periodic stocktake. And while it’s often a must for your end-of-year accounts, it’s hugely disruptive and usually reveals problems long after the damage is done.

There’s a much better way: cycle counting. Instead of tackling everything at once, you count small, manageable sections of your inventory on a regular, rotating basis—maybe daily or weekly. This approach is far less disruptive and helps you catch errors almost as soon as they happen.

So, what does this look like in practice? You could:

- Count by Location: Focus on one specific aisle, shelf, or bin each day.

- Count by SKU: Every Monday, you count your top 20 best-selling products.

- Count by Value (ABC): Check your high-value ‘A’ items more often (say, weekly) and your lower-value ‘C’ items less frequently (perhaps quarterly).

The aim is to make counting a low-stress, continuous part of your operations, not some dreaded annual event. This constant verification keeps the numbers in your system honest and truly reflects what’s on your shelves.

The Basics of Demand Forecasting

Once your stock data is accurate, you can start looking to the future. Demand forecasting is less about gazing into a crystal ball and more about using your past sales history to make educated guesses about what your customers will want to buy next. It’s the art of staying one step ahead, so you can avoid both frustrating stockouts and cash-flow-killing overstock.

This really is all about spotting patterns in your own data. Pull up your sales reports from the last 12-24 months and ask yourself a few questions:

- Trends: Are sales for a certain product generally climbing or falling over time?

- Seasonality: Do you see predictable peaks and troughs? Think about the Christmas rush, summer bank holidays, or the back-to-school season.

- Promotional Lifts: How did that last sale or marketing campaign affect specific products? Did you see a big spike?

Answering these helps you shift from reactive ordering (“Oh no, we’re out of stock again!”) to proactive, strategic planning.

For UK small businesses, getting this forward planning right is a massive challenge. A recent study found that a staggering 56% struggle with insufficient planning, which leads to costly overstocking or missed sales from understocking. It’s a critical issue for firms that collectively contribute 35% of the UK’s national turnover. Discover more insights from the inventory management report.

Setting Your Safety Stock Levels

Let’s be realistic—no forecast is ever perfect. An unexpected supplier delay, a sudden feature on a popular blog, or a TikTok video going viral can throw your best predictions out the window. That’s where safety stock comes in. It’s simply a small buffer of extra inventory you keep on hand to protect your business from these surprises.

How much you need depends on two key things: how much your sales tend to vary and how reliable your suppliers are. If you sell a product with very steady demand and your supplier is always on time, you’ll need very little safety stock. But if sales are all over the place and deliveries are unpredictable, you’ll need a much bigger cushion.

Getting this balance right means you can meet unexpected demand without tying up precious capital in stock that just sits there gathering dust.

Case Study: A UK Gift Shop’s Holiday Planning

Picture a small gift shop in York. Looking at last year’s sales data, the owner sees a massive 300% sales spike for scented candles and artisanal chocolates in November and December. Armed with this forecast, she places a much larger-than-usual order in late September to get well ahead of the Christmas rush.

She also remembers her main candle supplier had some delays last year. To hedge her bets, she increases her safety stock for her top three best-selling scents by 20%. This simple move ensures that even if a delivery runs late, she won’t run out of her most popular items during the busiest trading week of the year. This combination of forecasting and safety stock turns potential holiday chaos into a smooth, profitable season.

Answering Your Lingering Inventory Questions

Even with a solid plan, you’re bound to have questions as you put it all into practice. That’s perfectly normal. This is where we tackle some of the most common queries we hear from small business owners in the UK who are getting their stock under control.

Think of this as your go-to reference for those final, practical hurdles.

How Often Should I Really Do a Full Stocktake?

While your regular cycle counts are fantastic for keeping things accurate day-to-day, a complete, wall-to-wall physical stocktake is something you’ll need to do at least once a year. This is non-negotiable for your annual accounts and tax reporting, as it gives you a verified snapshot of your inventory assets at a specific moment.

That said, many businesses find it smart to do one more often. If you’re dealing with high-value goods or you keep finding annoying little discrepancies, shifting to a twice-yearly or even quarterly count can save a lot of headaches down the line.

My advice for a brand-new business? Do a full count every quarter for the first year. It feels like a lot, but it’s the fastest way to set a reliable baseline, catch problems in your process early, and get your counting methods dialled in.

What’s the Best Free Inventory Software for a UK Startup?

When you’re a startup, every penny counts. Luckily, there are some excellent software providers that offer “freemium” plans – free-forever tiers that are perfect for moving away from spreadsheets without the upfront cost.

Good places to start your search are Zoho Inventory or Odoo. Both have surprisingly capable free plans that can handle the essentials like tracking stock levels, managing orders, and pulling basic reports.

The “best” one for you will come down to what and how you sell.

- Selling Online? You’ll want a free plan that connects directly with your e-commerce platform, like Shopify or WooCommerce. Automating this link is a massive time-saver.

- A Tradesperson? Your priority might be a simple mobile app that lets you track stock in the van, making e-commerce integrations less important.

A word of warning: always read the small print on free plans. Look for the limits on how many products (SKUs), users, or monthly orders you can have. Make sure the free tier gives you enough runway to grow before you’re forced to upgrade.

How Do I Figure Out My Inventory Turnover Ratio?

Your Inventory Turnover Ratio is a key business health metric. In simple terms, it shows how many times you’ve sold and replaced your entire stock over a certain period. It’s a fantastic indicator of how well you’re selling and how efficiently you’re managing your stock.

The formula itself is pretty simple:

Cost of Goods Sold (COGS) / Average Inventory

To get your average inventory, just add your stock value at the start of the period to the value at the end, and then divide by two.

A higher ratio is generally a good sign – it suggests strong sales and lean stock management. A low ratio, however, might point to weak sales or, more commonly, that you have too much cash tied up in stock that’s just sitting there. Context is everything here; a “good” number for a bakery will be wildly different from that of a bespoke furniture maker, so compare your ratio to others in your industry.

What Is Safety Stock, and How Much Do I Need?

Safety stock, sometimes called buffer stock, is just that extra bit of inventory you keep on hand to guard against the unexpected. It’s your insurance policy against a sudden rush of orders or a supplier letting you down.

The aim isn’t to prevent every single stockout – that would be incredibly expensive. It’s about finding that sweet spot where you’re protected from common hiccups without tying up a fortune in idle products.

Here’s a simple formula to get you started:

(Maximum Daily Sales x Maximum Lead Time in Days) – (Average Daily Sales x Average Lead Time in Days)

This calculation provides a data-backed starting point. But don’t just follow it blindly. You need to apply your own business savvy. Is your supplier usually reliable? Is this a product your customers absolutely can’t wait for? Your answers to these questions will help you tweak that number until it feels right for your business.

Getting on top of your stock is a process of constant learning and tweaking. But once you have these foundations in place, it transforms from a headache into a powerful asset for growth. If you’re starting to burst at the seams and need a flexible, secure home for your inventory, Container Self Store offers practical and affordable business storage without locking you into a long-term lease. See how we can support your business.